Advantages:

• Reduced programming time

• Several options for different circumstances

• Easy programming

• Communicates with brake, not an

external resolver

Automation Method:

Part following is done by internal subroutines in the robot. The robot knows how far away it is from the press and its gripper orientation, so it can automatically follow the part without programming.

During programming the operator has several options as to how the robot will follow the part. By simply turning options on and off the robot knows how to follow the part. Some of the option are: with or without suction, return to gauging position, and pull or push the part during bending. |

|

|

| |

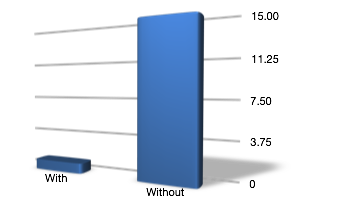

Programming Time per Bend

(minutes) |

|

|

|

|